Adjustability

It’s key to make things adjustable in your hardware. A good example of how devastating it can be to forget this can be seen in this clip:

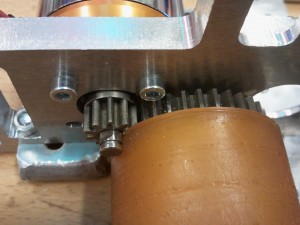

the robot to the right have the wheels too high up, so the magnets are in contact with the dohyo, and the wheels just spin in the air. probably they adjusted the height once on a table, but with the forces from the magnets, they chassi bent and needed re-adjustment. important things to make adjustable: plow height, motor mount, wheel height. with tons of unknown parameters, it is impossible to design something that will have the right settings directly

Tolerance

you find yourself grinding and fileing things a lot of the build time on your first robots, and the reason is the optimism about how things will fit in eachother. if you cnc-cut things, a “coincident” contact surface in CAD will have high likelyhood to cause problems.

Iterative design

go through many iterations, ask others about their opinions and don’t stick to one design just because you spent time developing it, if it turns out to be a bad design making a detailed design will take more time to implement, but will save time in the end, by not just having rectangular blocks stuffed together you will realize problems before you manufacture.

Design first, then buy&build

design and browse for parts simultaneously. don’t buy stuff before the design is locked down, unless it’s cheap. try to make design decisions based on available hardware.

Spare parts

get spare parts for everything. things will break, and they will break when there is no time to order new ones. a lot of robots have been stranded because one part got broken. it’s worth the extra cost in the time you will save.