since competing at RobotChallenge 2013 in Vienna with Sleipner and Lilla Lisa, i’ve got more and more excited about building a linefollower.

initial design-goals ( preliminary)

200g mass

3g acceleration sideways as well as accelerating/deaccelerating (all the way up to top-speed)

more than 5m/s top speed

vacuum fan. probably a 35-27mm EDF

size of max 25 x 25 cm to be able to compete in Robot-SM, Stockholm Robot Championship, Robotex and RobotChallenge

(just for calculations) wheel radius: 1cm

2s lipo

rought estimate of suitable components:

rpm on wheels at 5m/s: 4800rpm

since 2s lipo –> ca 7.4 volt system –> 4800/7.4=650kv on motor or equivalent with gearbox

power out of engine at 5m/s, 3g(=30m/s^2): P=F*V=m*a*V=5*30*0.2 =30W = 15W per motor

since there is no lightweight 650kv, 15w motors, i’ll have to use a gearbox. i like brushless outrunners, there are lots of variations but i’ve found some ca 10g 15W motor with about 2000kv, so a gear ratio of about 3:1 is needed.

2s lipo ,350mah, 65c 130c burst = 22A continous= 170W kont, 34g. http://www.hobbyking.com/hobbyking/store/__19117__Turnigy_nano_tech_350mah_2S_65_130C_Lipo_Pack.html

ESC wheel engines: 2s, 10A, 8g http://hobbyking.com/hobbyking/store/__23766__HobbyKing_Brushless_Car_ESC_10A_w_Reverse.html

ESC EDF: 10A, 9g http://www.hobbyking.com/hobbyking/store/__659__TowerPro_9g_w12A_Brushless_Speed_Controller.html

EDF: 27mm, 2s, 5.5A, 40W, 8g

wheel motors: http://www.hobbyking.com/hobbyking/store/__5358__18_11_2000kv_micro_brushless_outrunner_10g_.html

CAD for motors: https://grabcad.com/library/micro-brushless-motor-1

axle:

bearings: http://www.kullager.se/sv/product/501/Kullager-623-3x10x4

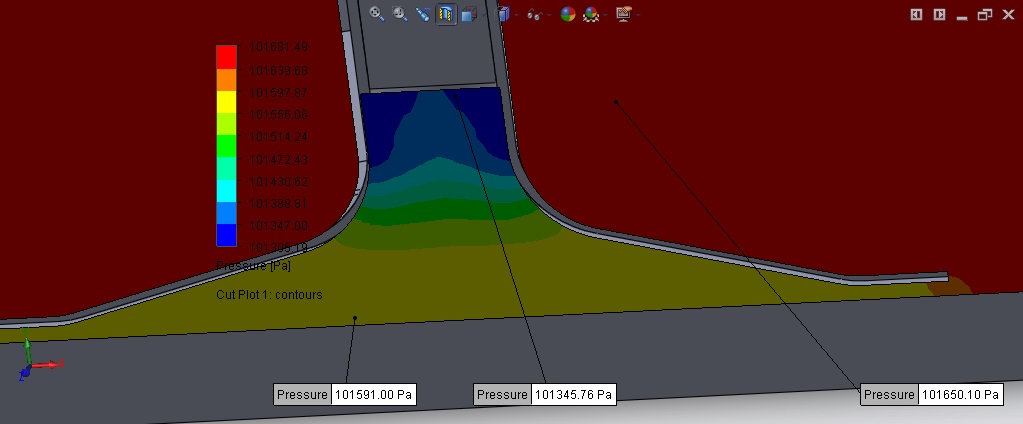

so far it seems as if 200g total is a reasonable and achievable goal. i will research more what kind of “diffusor” style undercarriage is the best shape to get as much downforce as possible with the EDF as a vacuum fan.